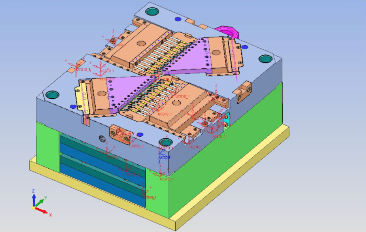

CAD CAM planning

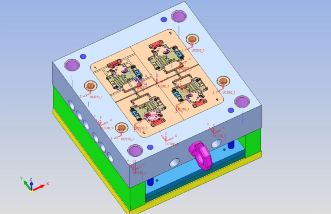

The customer’s design\product\files are analyzed by our technical office prior to the mould fabrication, in order to find out any possible feasibility problems. In some cases, they are modified in agreement with the customer in order to grant the success of the finished product.

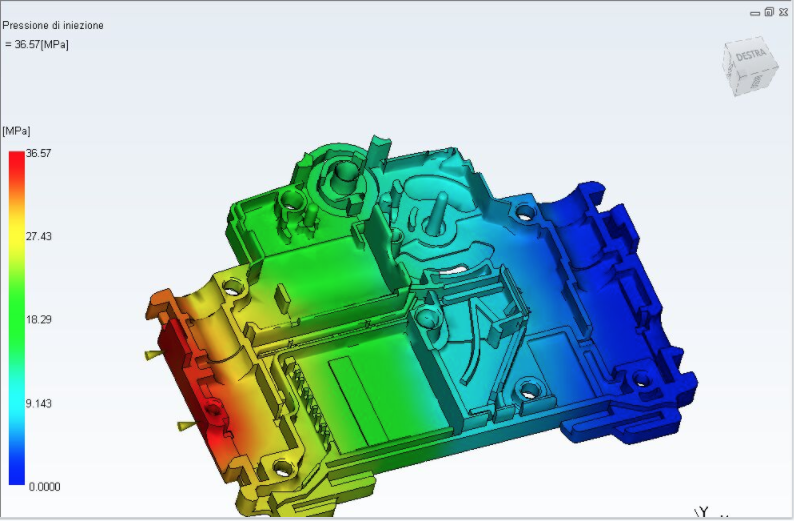

Our technical staff has worked since many years in the sector of moulds and injection printing of technical items; it makes use of highly specialized software for 3D-CAD modeling and CAM production, such as CIMATRON E and MOLD FLOW AUTODESK: powerful simulation softwares for the analysis of flows, deformations and possible aesthetic flaws.

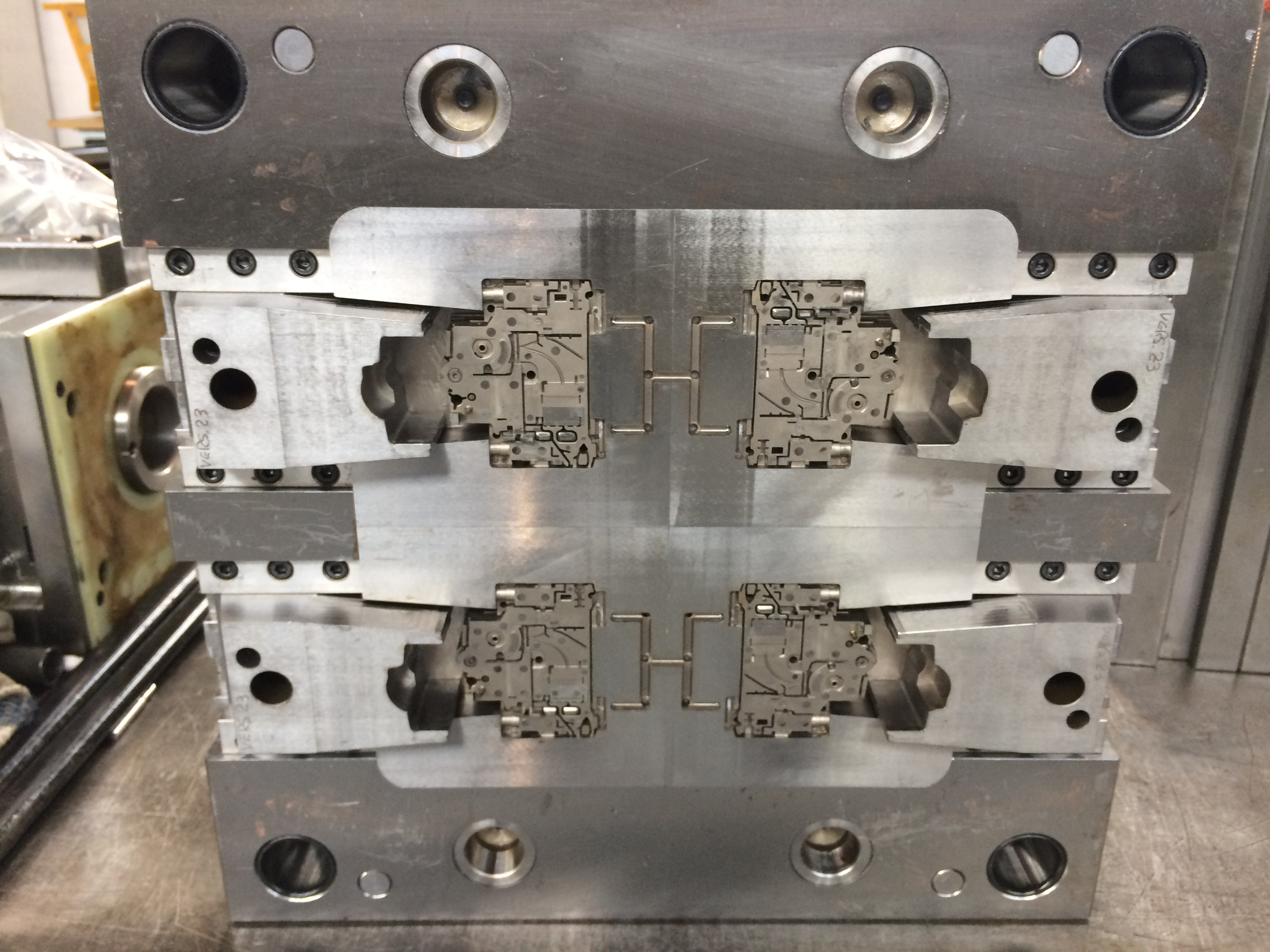

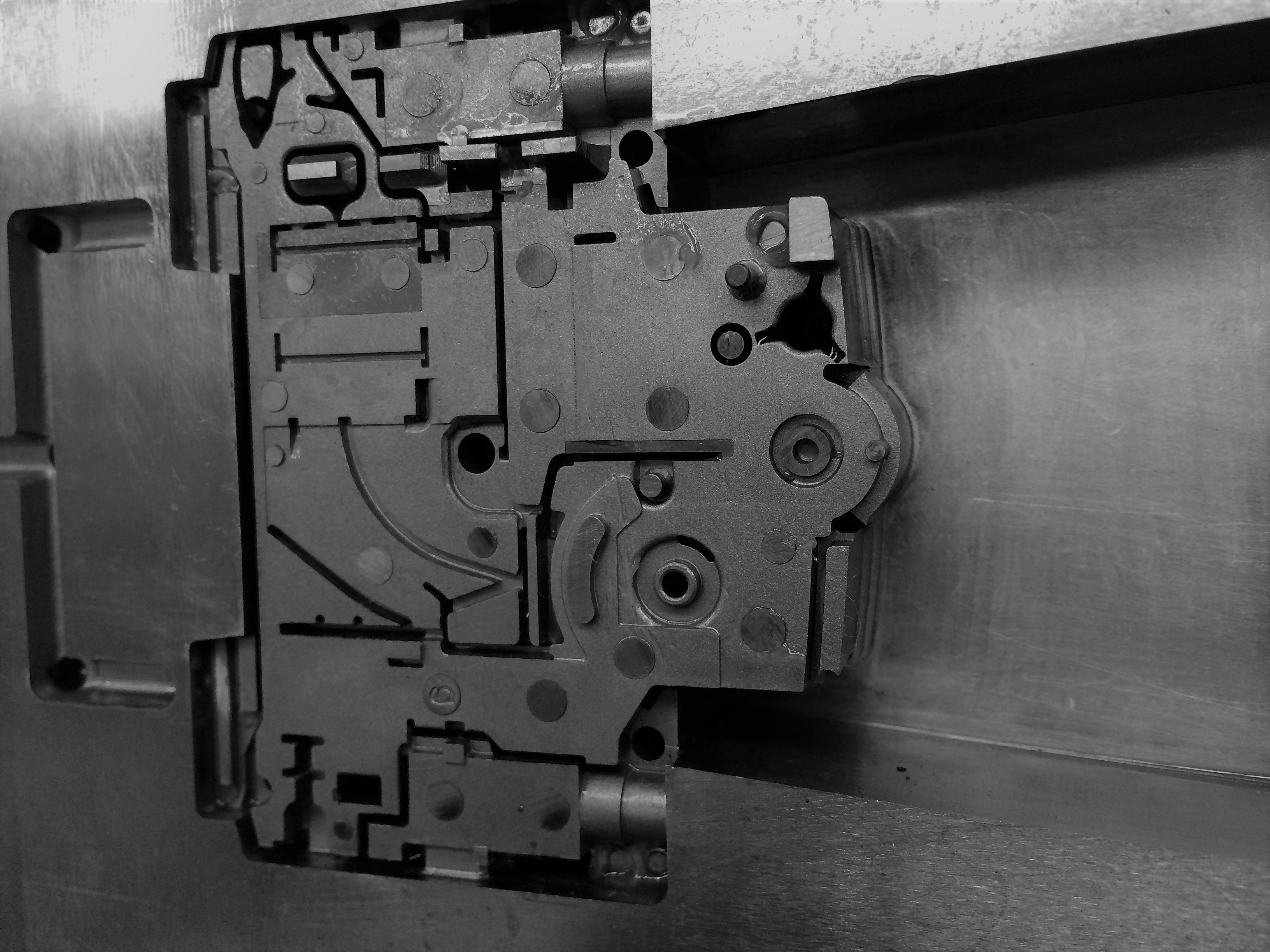

Mould production

Our workshop department for mould production has several last-generation machinery to meet the highest quality and lead-time requirements by the customers: electrical discharge machining (EDM), electrical discharge wire cutting (EDW), EDM pricker, CNC milling machines, lathes, tangential grinding, laser soldering machine, and more.

In more than 40 years of experience, OMED has been able to specialize in the creation of moulds subject to high requirements of precision and quality in the sector of electrical engineering, information technology, electrical appliances, and medicine.

One of OMED’s many strong points is the ready response to the customers’ requests to modify products, thanks to a continuous cooperation aimed at solving the problems stemming from the continuously evolving global market’s requirements.